Engineering Supervision of the Erection and Commissioning Works for Ingula Pumped Storage Scheme as South Africa’s largest hydro power project to date, 2016

May 7, 2016

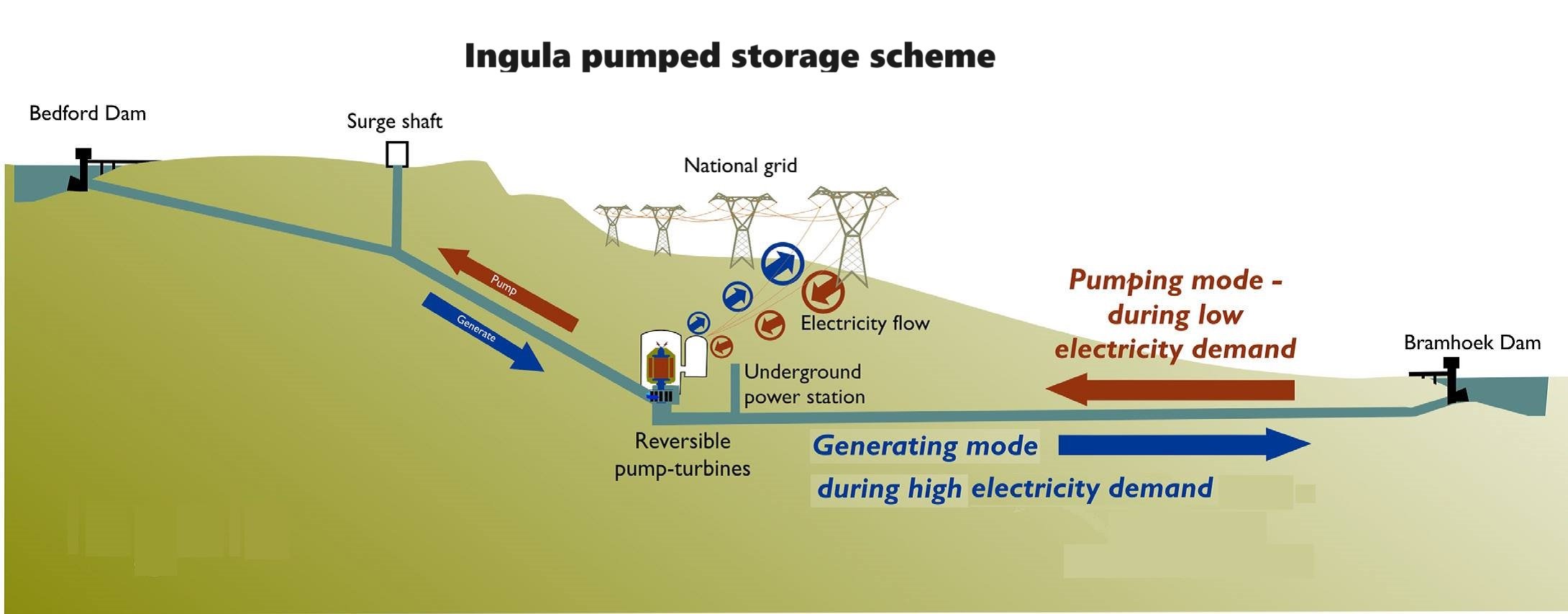

Operation of a pumped storage scheme

IBAKH is participating in Engineering Supervision of the Erection and Commissioning Works for Ingula Pumped Storage Scheme. The project site is located in north-east of Van Reenen's Pass, spanning the escarpment of the Little Drakensberg, and straddling the provincial boundary of the Free State and KwaZulu-Natal (KZN) provinces near the town of Ladysmith in South Africa. Site selection studies began in the 1980s and construction began in 2005. This project site location is also the continental watershed between the Vaal River catchment, flowing into the Atlantic Ocean, and the Thukela River catchment, flowing into the Indian Ocean. This scheme is the first of its kind in South Africa and designed to provide power to the high-voltage electric power transmission network (National Grid) during peak demand periods.

The main civil contractor as CMI JV, comprising CMC di Ravenna, PG Mavundla and Impregilo (underground civil works) led by Italian firms, has been awarded a contract by Eskom to construct the underground works and reservoirs for the Ingula project in March 2009 and project was originally scheduled to come on line during 2012, with a unit being commissioned each quarter, but in Jul 2009, the schedule was slipped a year for completion in 2013. This schemed is constructed by an Eskom (Owner and Operator) and CMI JV at a cost of USD3.5 billion. CMC Mavundla constructed main access tunnel.

This scheme comprises the Bedford Dam/Upper Reservoir, located in a tributary of the Wilge River, and the Bramhoek Dam/Lower Reservoir, situated in a tributary of the Klip River. Construction of the Bramhoek Dam used the Grout Enriched Roller Compacted Concrete (GE-RCC) and completed in November 2011, while the Bedford Dam used a concrete-faced rockfill design and completed in April 2011. Each reservoir, is capable of holding approximately 22 million cubic metres of water. Two reservoirs, 4.6km apart, are connected by underground waterways. The elevation between the two reservoirs affords a hydraulic head of 460 m with 80 m submergence. A 2 km long twin headrace tunnels(concrete and steel-lined: 6,6 m - nominal dia penstocks) connects the upper reservoir to the underground power station(The largest mudrock cavern in the world, totalling 200,000m³ : 150 m x 25 m main cavern together with a 160 m x 15 m transformer hall) which house 4 pump-turbine units. Water from the power station is discharged down Steel-lined extended draft tubes and a single 2.5 km long concrete-lined tailrace tunnel (9,0 m nominal dia.) to the lower reservoir. To generate electricity during times of peak demand, water is released from the upper reservoir, passing through the pump/turbines, into the lower reservoir. During times of low energy demand, the pump-turbines are used to pump the water from the lower reservoir, back to the upper reservoir.

This new 1334 MW pumped storage scheme is designed by a three-way Braamhoek Consultants Joint Venture (BCJV) as main project supervisor, consisting of Arcus GIBB (Pty), Stewart Scot International (SSI Engineers and Environmental Consultants, now known as Royal Haskoning) and Knight Piésold(design phases 1 and 2, construction design, supervision and dam construction):

GIBB responsibilities as leader of BCJV are: civil, mechanical and electrical engineering, detailed design, tender documentation, on-site design monitoring of access roads, dams, tunnels, caverns, mechanical and electrical works and construction supervision of all aspects of the project.

Royal HaskoningDHV has been involved at Ingula since the project began in 2005, as part of Braamhoek Consultants, a joint venture company set up to deliver five contracts within the bigger project. These include design and construction supervision for Ingula’s two dams – Bramhoek and Bedford, access roads, visitors centre and administration building and main underground works.

The main civil contractor as CMI JV, comprising CMC di Ravenna, PG Mavundla and Impregilo (underground civil works) led by Italian firms, has been awarded a contract by Eskom to construct the underground works and reservoirs for the Ingula project in March 2009 and project was originally scheduled to come on line during 2012, with a unit being commissioned each quarter, but in Jul 2009, the schedule was slipped a year for completion in 2013. This schemed is constructed by an Eskom (Owner and Operator) and CMI JV at a cost of USD3.5 billion. CMC Mavundla constructed main access tunnel.

This scheme comprises the Bedford Dam/Upper Reservoir, located in a tributary of the Wilge River, and the Bramhoek Dam/Lower Reservoir, situated in a tributary of the Klip River. Construction of the Bramhoek Dam used the Grout Enriched Roller Compacted Concrete (GE-RCC) and completed in November 2011, while the Bedford Dam used a concrete-faced rockfill design and completed in April 2011. Each reservoir, is capable of holding approximately 22 million cubic metres of water. Two reservoirs, 4.6km apart, are connected by underground waterways. The elevation between the two reservoirs affords a hydraulic head of 460 m with 80 m submergence. A 2 km long twin headrace tunnels(concrete and steel-lined: 6,6 m - nominal dia penstocks) connects the upper reservoir to the underground power station(The largest mudrock cavern in the world, totalling 200,000m³ : 150 m x 25 m main cavern together with a 160 m x 15 m transformer hall) which house 4 pump-turbine units. Water from the power station is discharged down Steel-lined extended draft tubes and a single 2.5 km long concrete-lined tailrace tunnel (9,0 m nominal dia.) to the lower reservoir. To generate electricity during times of peak demand, water is released from the upper reservoir, passing through the pump/turbines, into the lower reservoir. During times of low energy demand, the pump-turbines are used to pump the water from the lower reservoir, back to the upper reservoir.

This new 1334 MW pumped storage scheme is designed by a three-way Braamhoek Consultants Joint Venture (BCJV) as main project supervisor, consisting of Arcus GIBB (Pty), Stewart Scot International (SSI Engineers and Environmental Consultants, now known as Royal Haskoning) and Knight Piésold(design phases 1 and 2, construction design, supervision and dam construction):

GIBB responsibilities as leader of BCJV are: civil, mechanical and electrical engineering, detailed design, tender documentation, on-site design monitoring of access roads, dams, tunnels, caverns, mechanical and electrical works and construction supervision of all aspects of the project.

Royal HaskoningDHV has been involved at Ingula since the project began in 2005, as part of Braamhoek Consultants, a joint venture company set up to deliver five contracts within the bigger project. These include design and construction supervision for Ingula’s two dams – Bramhoek and Bedford, access roads, visitors centre and administration building and main underground works.

Knight Piésold was responsible for project management, dam type selection, geotechnical investigations, dam design, tender documents, construction supervision, and Operations and Maintenance Manuals.

Eskom has awarded a contract to Consortium of Voith Siemens Hydro and Fuji Hydro Power Generation in September 2008 for the main generating plant equipment supply to the Ingula project(pump-turbines, motor-generators and mechanical auxiliary plant). The contract is valued at €140-million (R1.65-billion). It had concluded a loan worth approximately R1 billion with the DB (Deutsche Bank) to fund 85 percent of the pump-turbines contract. DCD Heavy Engineering manufactured four Spiral Casings for Voith Siemens Hydro Power Generation and equiped Ingula pumped-storage project. Consortium of Voith Siemens Hydro and Fuji Hydro supplied the complete electro-mechanical equipment. This included four reversible Francis pump-turbines from Heidenheim of Germany, each with a capacity of 342 MW, the associated motor-generators (Manufactured at the Japanese plant in Kawasaki), as well as the entire control and automation systems. Recently Nippa Tech has signed a contract with Fuji Voith for Site Coordination and consulting for Ingula project site activities on motor-generator.

Here are other involved Sub-contractors and suppliers:

ABB (electrical balance of plant); Murray & Roberts (exploratory tunnel); Grinaker-LTA (access roads); Afriscan (water supply, sewage treatment, small access roads and building temporary Eskom offices); B&E Quanza Group (aggregate quarry); Acer [Africa] (environmental consultants); Braamhoek Dam JV (BDJV), comprising Concor Roads & Earthworks, Wilson Bayley Holmes-Ovcon, Edwin Construction and Silver Rock (dam contract); NCC Environmental Services (independent environmental control officer services); Konecranes (heavy-duty cranes); Letacla (fibre-optic communications); Siemens (generator transformers); Roshcon (line integration – main contractor); Optipower and Babcock Ntuthuko (line integration – subcontractors); and CBI and Prysmian (supply and installation of of 400 kV cables); RW Business Enterprises (surface drilling for dams); Drillcon (deep drilling for waterways); ABN Amro (business case review); Concor Mining and Murray & Roberts (exploration tunnel); T Patridge (geotechnical review); BKS (dam review); V Pysikowski (hydromechanical review); C Zdziarski (HVAC review); Grinaker/LTA (access roads); Afriscan (advanced infrastructure); B&E Quanza Group joint venture (quarry) and ARQ Consulting Engineers.

The schedule was slipped more thereafter to begin operations in late 2015, but the pump-turbine/motor-generator units were not commissioned as planned. The new target is set to have all four units commercially operational by July 2017. Unit-3 was synchronized on 6 Mar 2016.

Here are other involved Sub-contractors and suppliers:

ABB (electrical balance of plant); Murray & Roberts (exploratory tunnel); Grinaker-LTA (access roads); Afriscan (water supply, sewage treatment, small access roads and building temporary Eskom offices); B&E Quanza Group (aggregate quarry); Acer [Africa] (environmental consultants); Braamhoek Dam JV (BDJV), comprising Concor Roads & Earthworks, Wilson Bayley Holmes-Ovcon, Edwin Construction and Silver Rock (dam contract); NCC Environmental Services (independent environmental control officer services); Konecranes (heavy-duty cranes); Letacla (fibre-optic communications); Siemens (generator transformers); Roshcon (line integration – main contractor); Optipower and Babcock Ntuthuko (line integration – subcontractors); and CBI and Prysmian (supply and installation of of 400 kV cables); RW Business Enterprises (surface drilling for dams); Drillcon (deep drilling for waterways); ABN Amro (business case review); Concor Mining and Murray & Roberts (exploration tunnel); T Patridge (geotechnical review); BKS (dam review); V Pysikowski (hydromechanical review); C Zdziarski (HVAC review); Grinaker/LTA (access roads); Afriscan (advanced infrastructure); B&E Quanza Group joint venture (quarry) and ARQ Consulting Engineers.

The schedule was slipped more thereafter to begin operations in late 2015, but the pump-turbine/motor-generator units were not commissioned as planned. The new target is set to have all four units commercially operational by July 2017. Unit-3 was synchronized on 6 Mar 2016.

Posted by First Last.